1 Macchina di misura CMM DEA GLOBAL STATUS 7107 con testa rotante e scansione in continuo

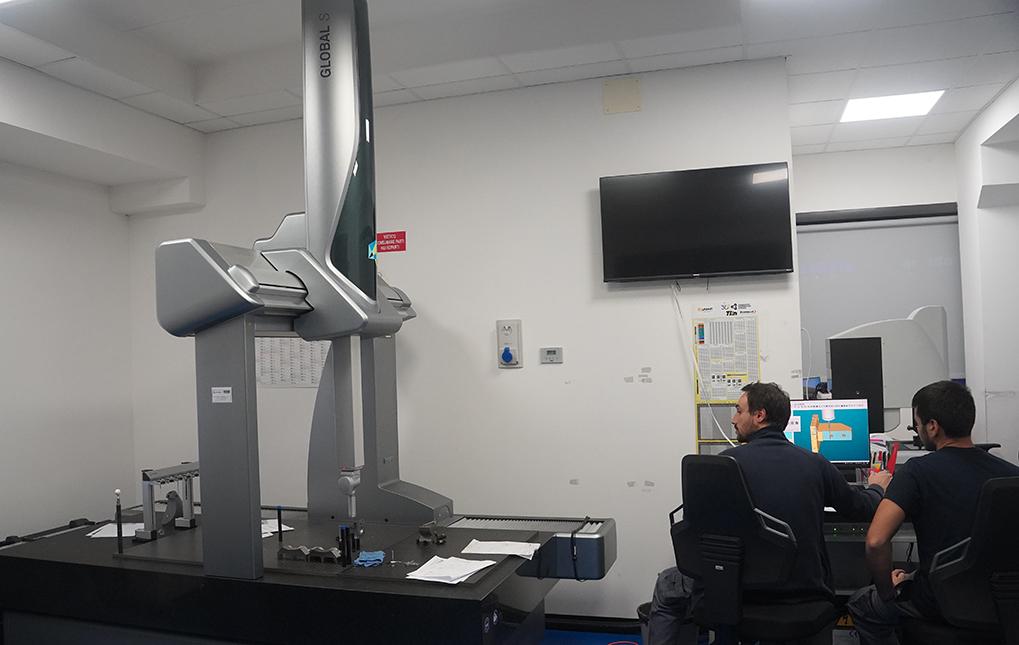

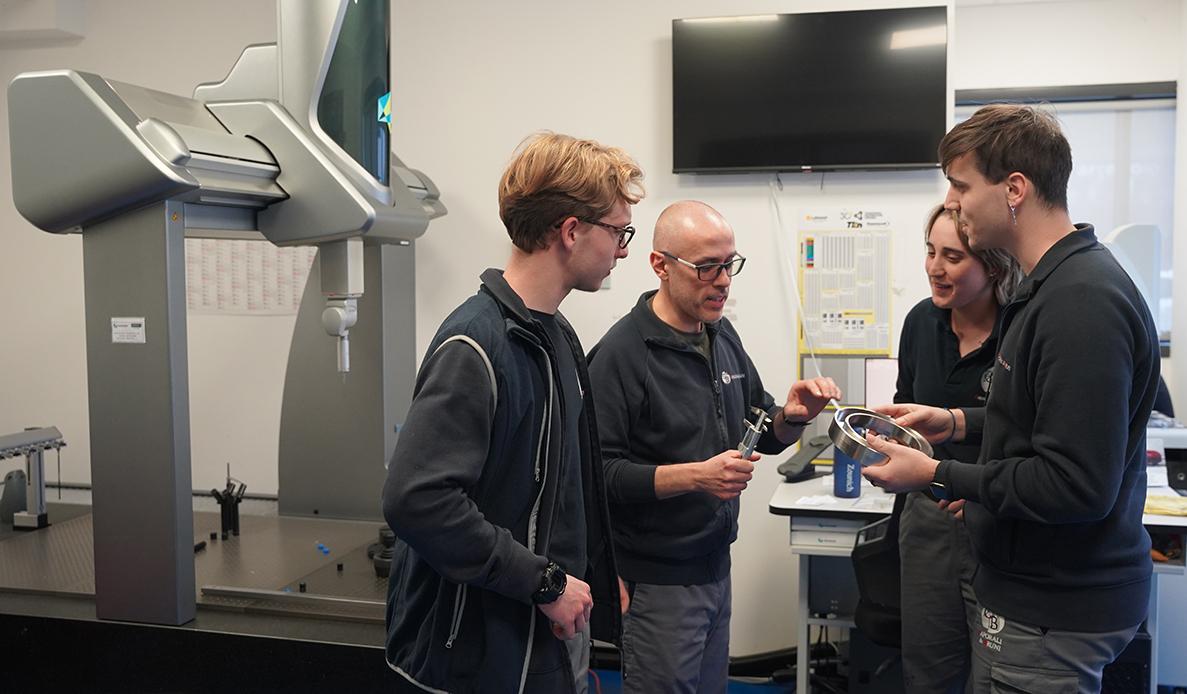

2 Macchina di misura CMM HEXAGON GLOBAL S BLUE 9158 con testa rotante e scansione in continuo

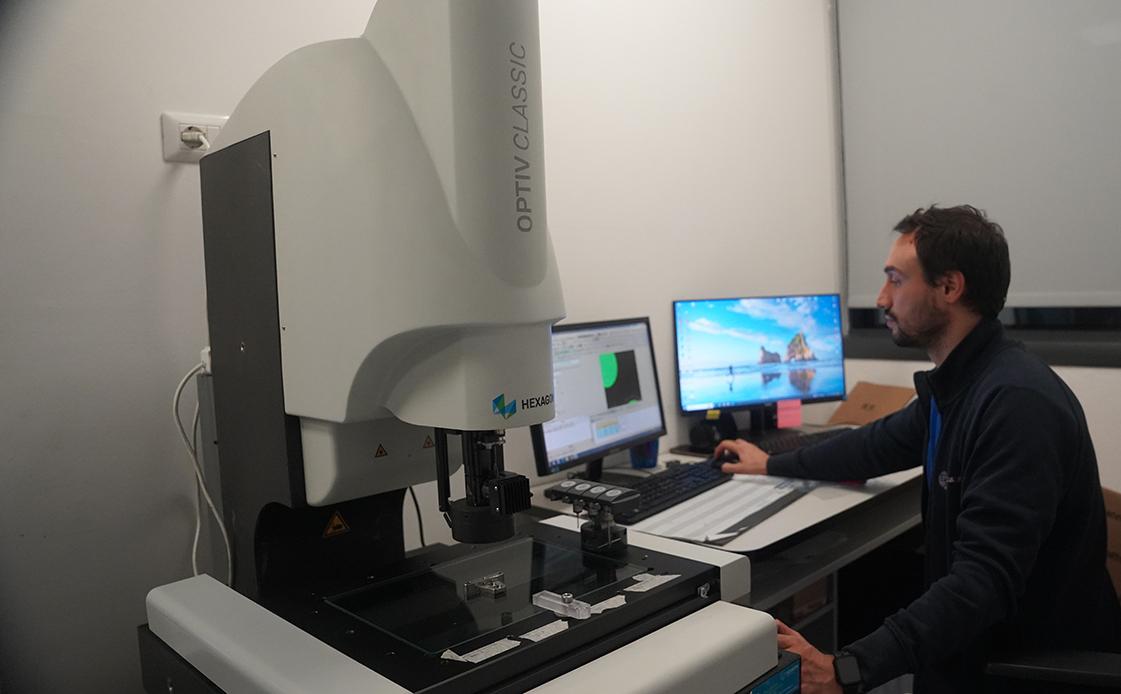

1 Macchina di misura ottica HEXAGON OPTIV CLASSIC 322

1 Braccio di misura 3D Laser Scanner Hexagon